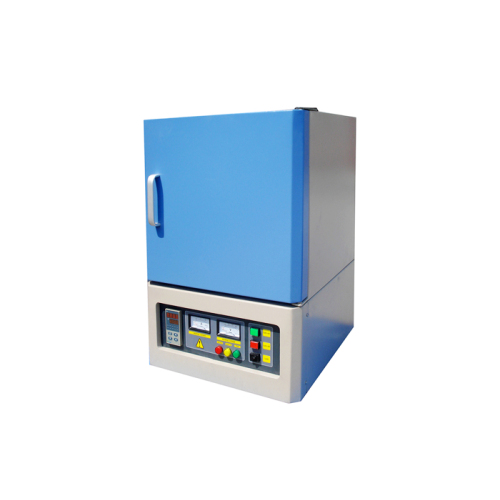

Muffle Furnace

1200℃ Muffle Furnace

BR-12N Muffle Furnace uses Resistance wire as heating elements, which can be used up to 1200℃. These compact muffle furnaces are perfect for many applications in laboratory. It is an ideal instrument for materials annealing and sintering in your research.

Features

1. Operation Temperature: 1100℃ (1200℃ for short time).

2. Maximum energy efficiency is achieved by surrounding the chamber with thermal-efficient alumina fiber ceramic insulation.

3. Heavy duty double layer structure with cooling fan. Lower temperature in outside case.

4. PID automatic control via current limiting phase angle fired the resistor, e.g. SCR (Silicon Controlled Rectifier).

5. Power control with 51 segments programmable

Quantity

Price EACH

TotalUS$ 40,000.00

You save$-40,000.00

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Description

| Ⅰ. Technical Specifications | |

| Max. temperature | 1200℃ (<2hour) |

| Working temperature | 1100℃ |

| Standard Temperature controlling | ● PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired, current limiting resistor. ● 50 programmable segments for precise control of heating rate, cooling rate and dwell time.

|

| Optional of Temperature controlling | ● Software (Furnace can be operated by PC by installing a control software) ● Touch screen temperature controller |

| Temperature accuracy | ±1℃ |

| Temperature Uniformity | ±5℃ over 120mm @ 1200℃ ±3℃ over 80mm @ 1100℃ |

| Heating rate | 0-20℃ /min |

| Thermocouple | K type (Pt-Rh) with 99.7% purity Alumina tube |

| Heating element | Fe-Cr-Al-Mo wire |

| Furnace Chamber | Two layers of ceramic fiber insulation materials ● First layer: 1430℃ ceramic fiber board. ● Second layer: 1260℃ ceramic fiber board. |

| Furnace structure | Double layer steel casing with dual cooling fan, surface temperature below 60℃ |

| Furnace door | ● Power cutting off when furnace door open |

| Warranty | ● One year limited warranty with life time support. (Consumable parts such as heating elements and crucibles are not covered by the warranty, please order the replacement at related products) ● ATTENTION: Any damages caused by the use of corrosive and acidic gases are not under the coverage of One Year Limited Warranty. |

| Certifications | CE |

| Ⅱ. Application Notes | |

| Using Attentions | ● Cooling rate shall also not exceed 10℃ /min. ● Toxic or explosive gases are not recommended for use with this furnace without necessarysafety controls and supervision. ● Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. ● Refractory door block must be inserted before closing door. |

Standard Size:

| Type | Max. Temperature(℃) | Furnace Chamber Size(mm) (Width x Height x Depth) | Volume(L) | Rated Power(kw) |

| BR-12N-1 | 1200 | 100x100x100 | 1 | 0.8 |

| BR-12N-2 | 1200 | 120x120x130 | 2 | 1.5 |

| BR-12N-3 | 1200 | 150x150x150 | 3 | 2 |

| BR-12N-5 | 1200 | 150x150x200 | 5 | 3 |

| BR-12N-8 | 1200 | 200x200x200 | 8 | 3.5 |

| BR-12N-12 | 1200 | 200x200x300 | 12 | 5 |

| BR-12N-27 | 1200 | 300x300x300 | 27 | 8 |

| BR-12N-36 | 1200 | 300x300x400 | 36 | 10 |

| BR-12N-64 | 1200 | 400x400x400 | 64 | 15 |

| BR-12N-125 | 1200 | 500x500x500 | 125 | 25 |

| BR-12N-216 | 1200 | 600x600x600 | 216 | 36 |

| BR-12N-512 | 1200 | 800x800x800 | 512 | 64 |

| BR-12N-729 | 1200 | 900x900x900 | 729 | 81 |

| BR-12N-1000 | 1200 | 1000x1000x1000 | 1000 | 100 |

| Note: | Special size is customized. | |||

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian